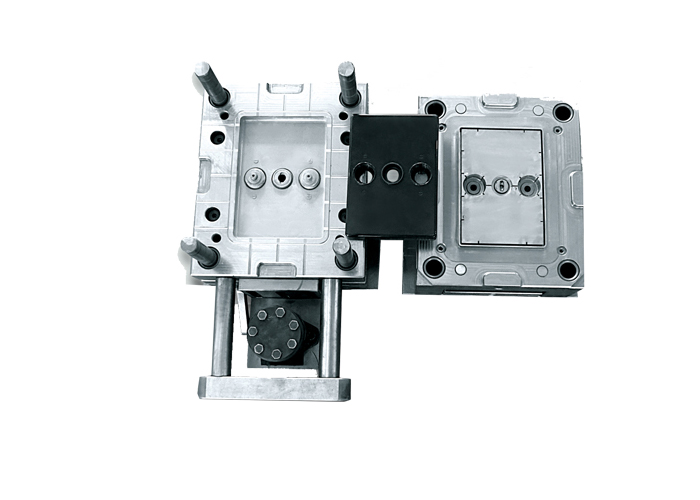

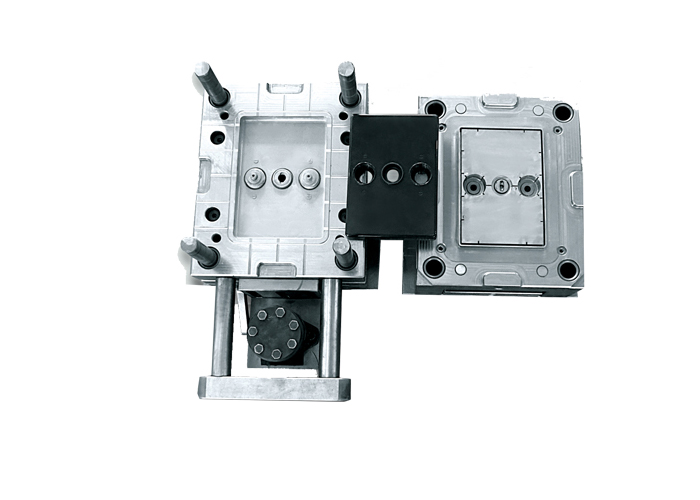

Precision Custom Plastic Injection Molding For Computer Accessories

The basic details

| Power source | electricity |

| Application | metal saw |

| rated voltage | 110v-240v |

| Rated Input Power | 2000W |

| No-Load Speed | 3800r/min |

| Frequency | 50/60Hz |

| Blade Diameter | 355mm |

| Max. Cutting Width | 60mm |

| Max. Cutting Depth | 60mm |

| Dimensions | 51*27*37cm |

| Weight: | 11 |

Quick Details

1. Cavities: single or as per your requirements cavity

2.Treatment: S45C Pretreat>25Hrc,And Nitriding

3. Hot runner: according to your demand

3. Life time: >300 Thousand Times

4. Package: Plywood case, anti-rust paint

5. Transport: By Sea or Air

6. Main process: Milling,grinding,CNC,EDM,wire-electrode cutting,

carved,electrospark,lathe,surface treatment

Main mould manufacture process Detail

1. Cap Mould : grinding→fly-cutter →CNC Milling→drilling→lathe→boring lathe→electric pulse →fine

fly-cutter→polish→electroplate→install

2. Preform Mould: grinding→drilling→lathe→boring lathe→fine fly-cutter→electroplate→install

What ‘s the Order process?

Step1: R&D

We support your R&D and make product design drawing as per

original sample or improve the mould drawing design if you want.

Step2: Negotiation

Make negotiation about the quality,price,material,delivery time and

payment,etc.

Step3: Place an order

You can place an order according your own design or choose by our

design.

Step4: Mould production

We will send mould design for customer approval first before the

mould production and then send samples to customer when finish the

process according to customer request.

Step5: Sample confirmation

Send mould test video and photos by email first and then send out

the samples by express for customer final confirmation.

Step6: Delivery

Pack moulds with wooden cases by sea or by air according to

customer’s requirement.

What are the specifications for plastic molding tools?

Name | moulds for power tool |

Mould material | P20 steel, 718, 2738, H13, NAK80, 2344, 2343, S316, M300,etc . |

Runner | Cold runner. Hot runner: Yudo/DME/HASCO |

Machine | 80-1600T |

Standard | HASCO, DME, LKM |

Specification drawings | Pro/E, Auto CAD, Solidwork, CAXA UG, CAD/CAM/CAE. |

Precision machining | CNC, milling machine, drilling machine, numerical lathe, all types

of lathe |

Surface finish process | polishing, sand blasting, heat treatment, painting, powder coating,

anodizing,

electroplating, mirror polishing . |

Shaping mould | injection mould |

Mould life | above 500000-1000000 shots and up |

Service | OEM service available, good after-sales service . |

Lead time | 4-7 weeks, 40 days or according to the real situation . |

Plastic material | PP, ABS, HDPE, PC, PVC ect |

Cavity Number: | Single or multi cavity |

Delivery: | by air or by sea. |

Our business line

1. Household / home appliance moulds: plastic chair, table,

buckets, bowel,bottle,laundry basket, trash bin, kitchenware

,plastic sanitary ware mould, plastic container mould ,etc.

2. Battery box / container moulds:car battery mould,motocycle

battery mould,UPS battery mould,EV battery mould,Industrial battery

mould,,etc.

3. Medical moulds: Medical device, monitor, actual tray rack,

reagent bottle holder, syringe.

4. Other moulds: auto parts mould ,power tool injection

mould,customize plastic injection moluld,Other OEM mould.

5. Plastic vent plug.

What are the features for plastic molding tools?

1.They are Mainly use NAK80 mold material in good polishing

performance, good appearance and high hardness.

2.Easy to process, suitable for EDM processing.

3.long life time, can reach more than 500000-1000000 shouts and up

4.Creative design, customizable.

5.high precision, use CNC, milling machine, drilling machine,

numerical lathe, all types of lathe and so on.

What are the applications for plastic molding tools?

Plastic molding tools are with very wide applications for our daily

necessities, instruments, automobiles, shoes, medical, tableware,

crafts, food, mobile phones, electronics, appliances and so on.They

make our lives easier ,more effeient,and more convenient.

Why choose us ?

1. Competive price,High quality raw material,Advanced and

professional facility,perfect procedure.

2. Excellent design and OEM service

3. Short lead time

4. Efficient team and experienced engineers

What kind of services we provide for ?

Free product design &mould design 2D/3D

Free sample delivery, 3 times mould test

Every week update production information.

Mould one year guarantee, Mould full-life technique support