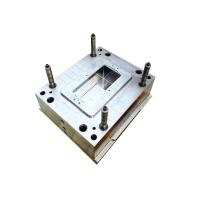

Plastic Injection Mold Tooling Hot Runner Multi Cavity High

Polished

FBR mould is known as one of the professional manufacturers and

exporters for plastic vent plug and plastic injection molding tools

for battery box / container mould,car battery mould,auto parts

mould,power tool injection mould,medical mould ,home appliance

mould plastic bucket /bowel mould and so on. OEM is available.We

have rich export experience and strict quality control .

We guarantee good quality and competitive price. FBR mould always

keep in touch with customer in every step to ensure that all the

details are in accordance with customer request.

Order Procedure

Step1: R&D

We support your R&D and make product design drawing as per

original sample or improve the mould drawing design if you want.

Step2: Negotiation

Make negotiation about the quality,price,material,delivery time and

payment,etc.

Step3: Place an order

You can place an order according your own design or choose by our

design.

Step4: Mould production

We will send mould design for customer approval first before the

mould production and then send samples to customer when finish the

process according to customer request.

Step5: Sample confirmation

Send mould test video and photos by email first and then send out

the samples by express for customer final confirmation.

Step6: Delivery

Pack moulds with wooden cases by sea or by air according to

customer’s requirement.

Trade Terms

| 1. Payment: L/C, T/T, D/P, Western Union,Paypal |

| 2. Production lead time: 25~30 days upon deposit |

| 3. Sample can be ready in 4 weeks |

| 4. Shipping freight are quoted under your requests |

| 5. Shipping port: Ningbo or Shanghai Mainland China |

Application

Communication/Electronic/Auto parts/Surveillance products/Medical

device/equipment and so on

About the Cold runner and hot runner

Cold runner systems are used in injection molding machines to

convey material from the nozzles to the mold cavity. The material

cooled in the channel between the nozzle and the cavity (the

runner) and ejected with the part.

A hot runner system is an assembly of heated components used in

plastic injection molds that inject molten plastic into the

cavities of the mold.

Plastic Injection Solution

1. Precision Injection Molding: From design consultancy & prototype

tooling to high-volume world-class production

2. Parts are widely used: Industrial, Automotive, Electronics &

Medical

Basic Information

Mold type: all tyes of produts plastic mould

Mould base material: #45.LKM, LYM

FAQS

1: Which kind information need for quotation in FBR MOULD?

1), Sample photo with size or 2D/3D design

2), Cavity quantity

3), Runner type, cold or hot

4), Mould steel type,P20, 718, 2738,H13,S136,2316,an so on.

5), Injection machine parameter or plate size(tie rod distance)

2: Delivery time in FBR MOULD

3~15 days for mould design, 15~60days for mould production after

deposit payment and mould design confirmed

3: Payment Terms in FBR MOULD

TT, L/C, Western Union, Paypal

4: Shipping Type in FBR MOULD

By Air Or By Sea

5: Guarantee in FBR MOULD

One year guarantee

6: Why choose FBR MOULD?

FBR Mould Factory is the leading plastic mould manufacturer in

China, based on precise tooling, high technology and top mentality

mould design.

Design

We are professional for mould design, our technique absorbed from

Taiwan and Europe.

Quality

All of our mould steel have certificate with longer mould life,

mould produced by advanced equipment, the tolerance can reach

+-0.01mm,the molded product have good appearance without any flash

and good fit with other products.

Price

We always provide competitive price, because of we are

manufacturer, we are the source.